Titanium

Introduction of Titanium

Titanium (or Ti on the periodic table) is a lightweight metal with a wide range of useful properties from corrosion resistance to strength retention at extreme temperatures. You can purchase it both in pure and alloyed form. Note that even pure titanium has some (less than 1%) iron and oxygen content. More advanced alloys significantly improve the overall strength of titanium.

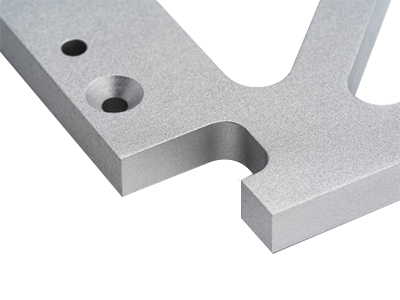

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries. Select Titanium CNC machining in the BatCNC ™.

Information of Titanium

Feature

Information

Subtypes

Titanium (Grade 2), Titanium (Grade 5)

Process

CNC machining, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium

Applications

Aerospace fasteners, engine components, aircraft components, marine applications

Finishing Options

Media Blasting, Tumbling, Passivation

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(MPa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Brass C260

275 to 410

300

20

149

4.51

Brass C360

880

240

14

334

4.43