Stainless Steel

Introduction of Stainless Steel

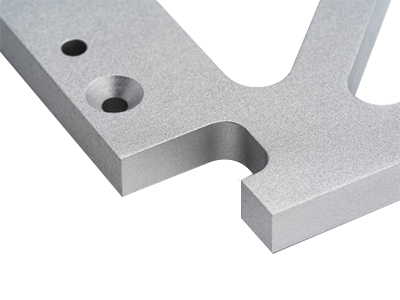

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

The material properties associated with stainless steel have made it a popular metal within a broad range of industries, including construction, automotive, aerospace and more. Within these industries, Stainless steel is versatile and is an effective choice for many applications.

Information of Stainless Steel

Feature

Information

Subtypes

15-5, 17-4, 18-8, 303, 304, 316, 416, 420, 440C, 410,

Process

CNC machining, injection molding, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium

Applications

Industrial applications, fittings, fasteners, cookware, medical devices

Finishing Options

Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Subtypes

Tensile Strength,

Yield (MPa)

Shear Modulus

(GPa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

15-5

1208

75

9.8

420

7.8

17-4

1090

77.4

6

352

7.70

18-8

215

77.2

40

228

8

303

415

68.9

12

73

2.7

304

215

77

70

123

8

316

290

74

50

217

8

416

600

83

20

237

7.8

420

345

75

25

241

7.8

440C

445

83.9

14

223

7.8

410

1225

73

14.5

422

7.8