Copper

Introduction of Copper

Copper is listed as Cu (atomic number 29) on the periodic table and is an excellent conductor of electricity and heat, second only to silver. Commercially available copper is typically more than 99% pure. The remaining 1% is usually impurities such as oxygen, lead, or silver.

Copper is well known for its electrical and thermal conductivity. It is very resistant to corrosion and is also inherently antimicrobial. The power, automotive, medical, and aerospace industries make use of copper specifically for these properties. Select Copper CNC machining in the BatCNC™.

Information of Copper

Feature

Information

Subtypes

C101, C110

Process

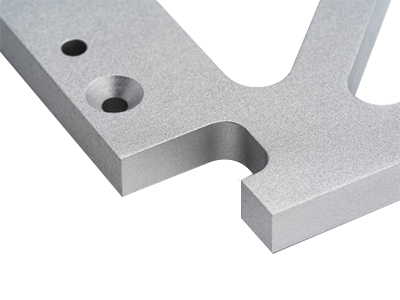

CNC machining, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768

Applications

Bus bars, gaskets, wire connectors, and other electrical applications

Finishing Options

Available as-machined, media blasted, or hand-polished

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(Mpa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Copper C101

69-365

90

55

81

8.89-8.94

Copper C110

76

76

45

57

8.89