Bronze

Introduction of Bronze

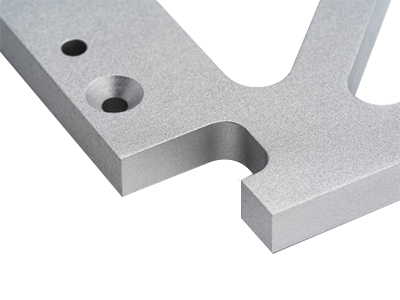

Bronze is made by mixing copper with up to approximately 35% tin and up to 8% lead. The inclusion of lead alloy, which is a soft metal, is what makes it so machinable. Bronze is great for applications such as bearings as well as marine applications on pumps and fittings where corrosion resistance against seawater is required. This material’s mechanical properties don’t quite measure up to many other machinable metals, so it is best used on low-stress components made with CNC machining.

Bronze, brass, and other copper alloys have a range of important electrical, mechanical, and corrosion-resistant properties. Specifically, bronze has excellent machinability, with an index of 100%. It also has low friction properties that make it ideal for parts that undergo continuous frictional contact.

Information of Bronze

Feature

Information

Subtypes

C932

Process

CNC machining, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768

Applications

Bus bars, gaskets, wire connectors, and other electrical applications

Finishing Options

Available as-machined, media blasted, or hand-polished

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(Mpa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Bronze C932

125

110

20

65

8.93