Brass

Introduction of Brass

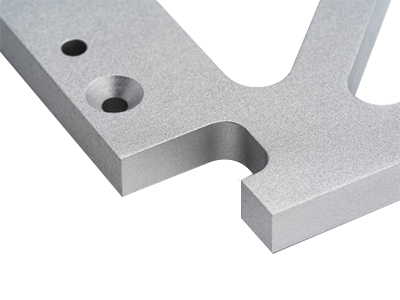

Brass is the name used for a wide range of copper-zinc alloys. These alloys vary by the amount of zinc as well as the inclusion of other alloying elements such as lead, aluminum, and iron. Brass is thermally and electrically conductive thanks to its copper content. It also has good wear resistance. The inclusion of lead improves machinability, making brass the most machinable of all the copper alloys. Choose Brass CNC machining in the BatCNC™.

Brass is a versatile copper alloy that retains some of the benefits of copper but also improves on some of its attributes. Brass is a mechanically stronger and lower-friction metal, and offers better corrosion and wear resistance than basic copper. These properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Information of Brass

Feature

Information

Subtypes

C260, C360

Process

CNC machining, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium

Applications

Gears, lock components, pipe fittings, and ornamental applications

Finishing Options

Media blasting

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(Mpa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Brass C260

75

90

68

53

8.53

Brass C360

124-310

138

53

63-130

8.49