Aluminum

Introduction of Aluminum

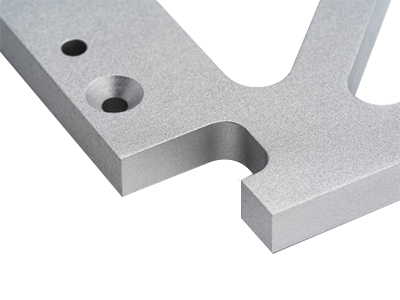

Aluminum is a lightweight metal with an excellent strength-to-weight ratio, making it ideal for applications in which metallic-level strength is required, but mass is still a concern. There are various alloys for aluminum, each denoted by the first number in their classification. The number indicates the main alloying element(s).

Aluminum is one of the most common materials used in the aerospace, medical, and automotive industries. This is due to its excellent strength-to-weight ratio, formability, and general versatility. Choose aluminum CNC machining in the BatCNC™️.

Information of Aluminum

Feature

Information

Subtypes

2024-T3, 5052, 6061, 6063, 7050, 7075, MIC-6, etc

Process

CNC machining, injection molding, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium

Applications

Light & economical, used from prototyping to production

Finishing Options

Alodine, Anodizing Types 2, 3, 3 + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(Mpa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Aluminum 2024-T3

324

138

19

120

2.78

Aluminum 5052

193

117

18

60

2.68

Aluminum 6061

276

96.5

17

95

2.7

Aluminum 6063

214

68.9

12

73

2.7

Aluminum 7050

490

160

11

147

2.83

Aluminum 7075

503

159

11

150

2.81

Aluminum MIC-6

105

n/a

3

65

2.7