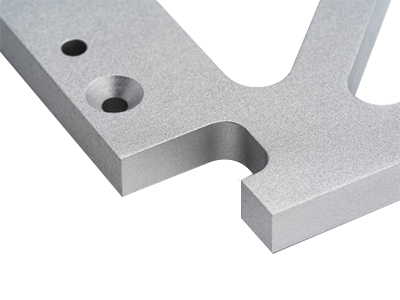

Large-Size CNC Machining Service

With over 30 sets of Large size CNC turning and milling machines, and offer 100+ different types of materials and surface finishes, guaranteeing quick turnaround and quality of one-off prototypes and production parts.

How BatCNC™ Works

Based on our professional large-scale processing equipment and many years of manufacturing experience, BatCNC™ provides all customers with the most cost-effective processing services.

Start Machining

After you confirm the machining, price, and shipping time, we will start the machining for the parts. We will notify each key processing node by email

Arrange the shippment

Once the part is completed, the quality inspection will be released. After confirmation, they will be packed in wooden crate and delivered to you by sea or air Safely.

Why Choose BatCNC™

10+ Years for Large-Size

With a decade of experience in large parts machining, we offer expertise, efficiency, and quality. This advantage ensures tailored solutions for diverse projects, making us a reliable choice for large parts machining.

Cost-Effective Quote

Benefitting from years of expertise and a skilled team, our machining prices offer exceptional value. We provide cost-effective solutions without compromising quality, ensuring affordability and top-notch service.

Quality Assurance

We rigorously adhere to a quality management system, guaranteeing consistent, expected product quality. Comprehensive inspections further ensure the delivery of precision machined parts free from unwanted defects.

24/7 Engineering Support

Wherever you are, our 24/7 engineering support is accessible year-round. Our seasoned engineers can guide you in part design, material selection, surface finishing, and lead time, ensuring the most suitable solutions for your needs.

CNC Machining Tolerances and Standards

BatCNC™ is your perfect partner for precision CNC machining services, crafting accurate prototypes and parts. Our standard CNC machining tolerances are ISO 2768-f for metals and ISO 2768-m for plastics. If you need specific tolerances, just specify them on your drawing, and we’ll meet your requirements.

Standards

CNC Turning

CNC Milling

Minimum Part Size

φ2300 x 5000 mm

φ90.5 x 196.8 in.

4000 × 1500 × 600 mm

157.5 × 59.1 × 23.6 in.

Maximum Part Size

2×2 mm

0.079×0.079 in.

4×4 mm

0.1×0.1 in.

Standard Tolerances

Metals: ISO 2768-f

Plastics: ISO 2768-m

Metals: ISO 2768-f

Plastics: ISO 2768-m

Linear Dimension

+/- 0.03 mm

+/- 0.001 in.

+/- 0.03 mm

+/- 0.001 in.

Hole Diameters

+/- 0.03 mm

+/- 0.001 in.

+/- 0.03 mm

+/- 0.001 in.

Shaft Diameters

+/- 0.03 mm

+/- 0.001 in.

+/- 0.03 mm

+/- 0.001 in.

Edge Condition

Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer,

or resulting radii, must be indicated on the drawing.

Threads and Tapped

Holes

Diameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×

diameter

Diameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×

diameter

.

We can produce threads of any specification and size required by our customers.

Text

Minimum width: 0.5 mm, depth: 0.1 mm

We can use CNC engraving or laser carving

to create standard text based on customers’

requirements.

We can use laser marking to create standard

text for CNC turned parts.

Lead Time

7-15 days

Materials for Large-Size CNC Milling Parts

CNC machines work with numerous materials, offering diverse choices for rapid prototyping and custom complex part production. We offer instant quotes for 100+ metals and plastics, allowing you to compare prices for different machining materials to meet your manufacturing requirements.

Surface Finishes for Large-Size CNC Milling Parts

CNC machines work with numerous materials, offering diverse choices for rapid prototyping and custom complex part production. We offer instant quotes for 100+ metals and plastics, allowing you to compare prices for different machining materials to meet your manufacturing requirements.

More Resources on BatCNC™

We continuously update materials, surface treatment, industry knowledge, and successful cases through different sections.