Zinc

Introduction of Zinc

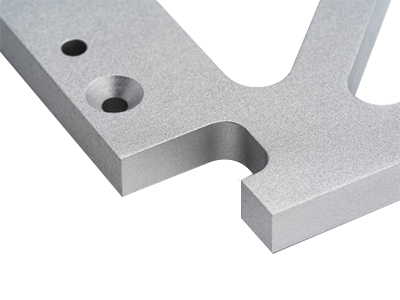

Zinc (denoted as Zn on the periodic table) is a relatively common non-magnetic metal. It is typically alloyed with aluminum, magnesium, and copper. This class of zinc alloy is referred to by the name Zamak (the term originated as an acronym for the element names in German: “Zink, Aluminium, Magnesium, and Kupfer”). These alloys are usually supplied in the form of ingots due to their extensive use in die-casting applications. Zinc has excellent damping capacity; it is highly ductile and exhibits long-term dimensional stability. Die-cast Zamak alloys maintain high levels of precision and therefore require less machining to bring the part into the required tolerances.

Zinc alloy metal is some of the cheapest materials available. Despite a low price point, they have good mechanical strength, are easily machined, and resist mechanical shocks well. Complex components are often initially die-cast and then have critical features machined into them, reducing overall CNC machining time and cost. The automotive industry makes extensive use of CNC machined zinc alloys.

Information of Zinc

Feature

Information

Subtypes

Zamak 3 (Zinc alloy 3)

Process

CNC machining, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768

Applications

cosmetic vehicle parts, complex part housings, and fuel system components

Finishing Options

Available as-machined, media blasted, or hand-polished

Subtypes

Tensile Strength,

Yield (MPa)

Fatigue Strength

(Mpa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Zamak 3

(Zinc alloy 3)

208

48

10

82

6.6