Steel

Introduction of Steel

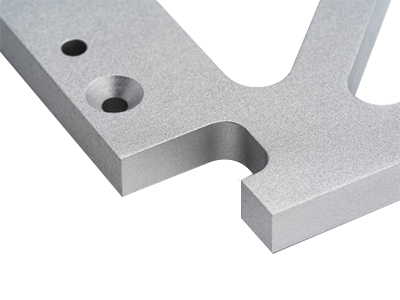

Steel is an alloy of iron with approximately 1% carbon. Small amounts of other alloying elements like molybdenum and chromium may be added to improve its properties. Steel offers a great balance between cost and functionality since it is easy to machine and weld. It will, however, oxidize over time and therefore needs surface treatments for protection.

Steel is one of the most widely used manufacturing materials and is used in every major industry from construction to automotive. Its cost-effectiveness coupled with some very useful properties makes it a versatile material. Listed below are some of the mild steel variants and high-strength steel variants BatCNC™ offers in CNC machining.

Information of Steel

Feature

Information

Subtypes

1018, 4130, 4140, 4140 PH, A36, 1215, 4340, A2 Tool Steel, O1 Tool Steel

Process

CNC machining, injection molding, sheet metal fabrication

Tolerance

With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium

Applications

Fixtures and mounting plates; draft shafts, axles, torsion bars

Finishing Options

Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating

Subtypes

Tensile Strength,

Yield (MPa)

Shear Modulus

(GPa)

Elongation at Break

(%)

Hardness

(Brinell)

Density

(g/cm^3)

Steel 1018

310

78

20

131

7.87

Steel 4130

460

80

21.5

217

7.85

Steel 4140

655

80

25.7

197

7.85

Steel 4140 PH

1241

80

14

429

7.8

Steel A36

250

79.3

20

119

7.85

Steel 1215

415

80

10

167

7.87

Steel 4340

470

74

22

217

7.85

A2 Tool Steel

415

78

21

57 to 62 HRC

7.86

O1 Tool Steel

400

77

20

63 to 65 HRC

7.83